The vertical turret milling machine is a versatile tool used in metalworking and manufacturing processes. It is composed of several key components, each serving a specific function. In this article, we will break down the turret milling machine into its various parts and discuss the accessories that make up its machine head.

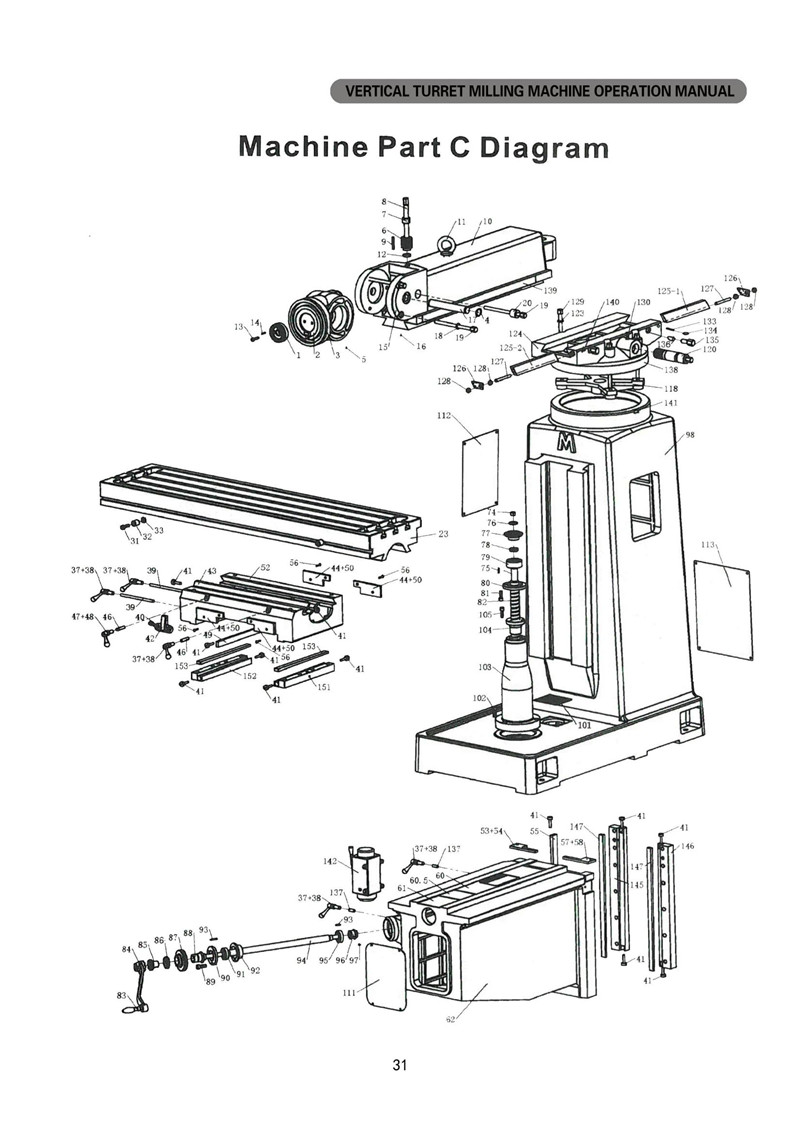

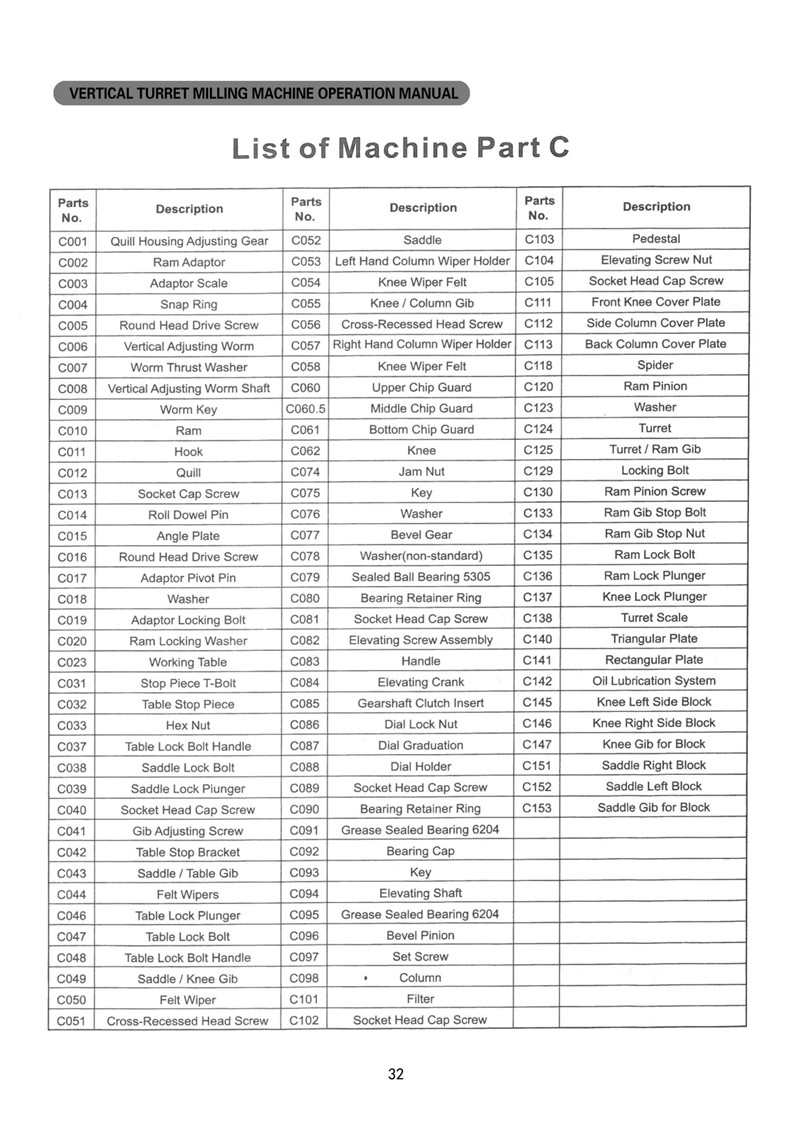

Part 1: Base and Column

The base and column form the foundation of the vertical turret milling machine. The base provides stability and support, while the column houses the vertical and horizontal movement mechanisms. These components are essential for maintaining the machine's structural integrity and ensuring precise machining operations.

Part 2: Knee and Saddle

The knee and saddle are responsible for controlling the vertical and horizontal movement of the workpiece. The knee can be adjusted to different heights, allowing for precise positioning of the workpiece, while the saddle enables smooth movement along the machine's axis. These components are crucial for achieving accurate and consistent milling results.

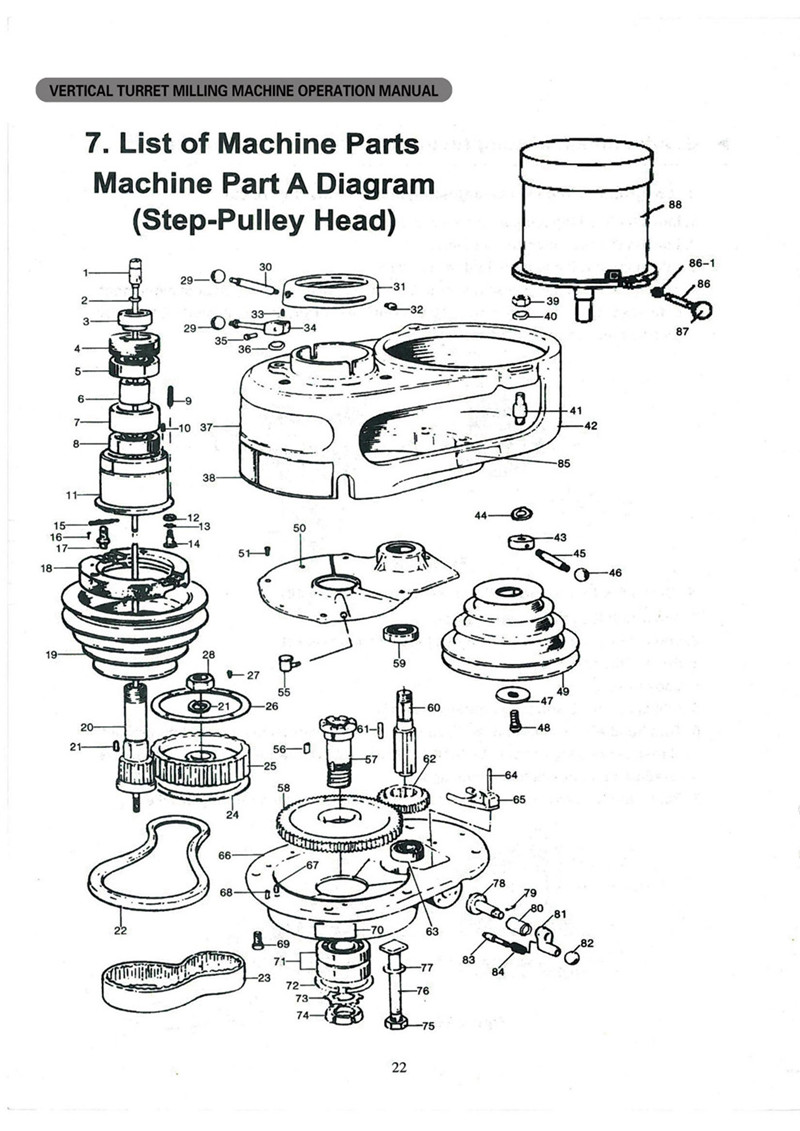

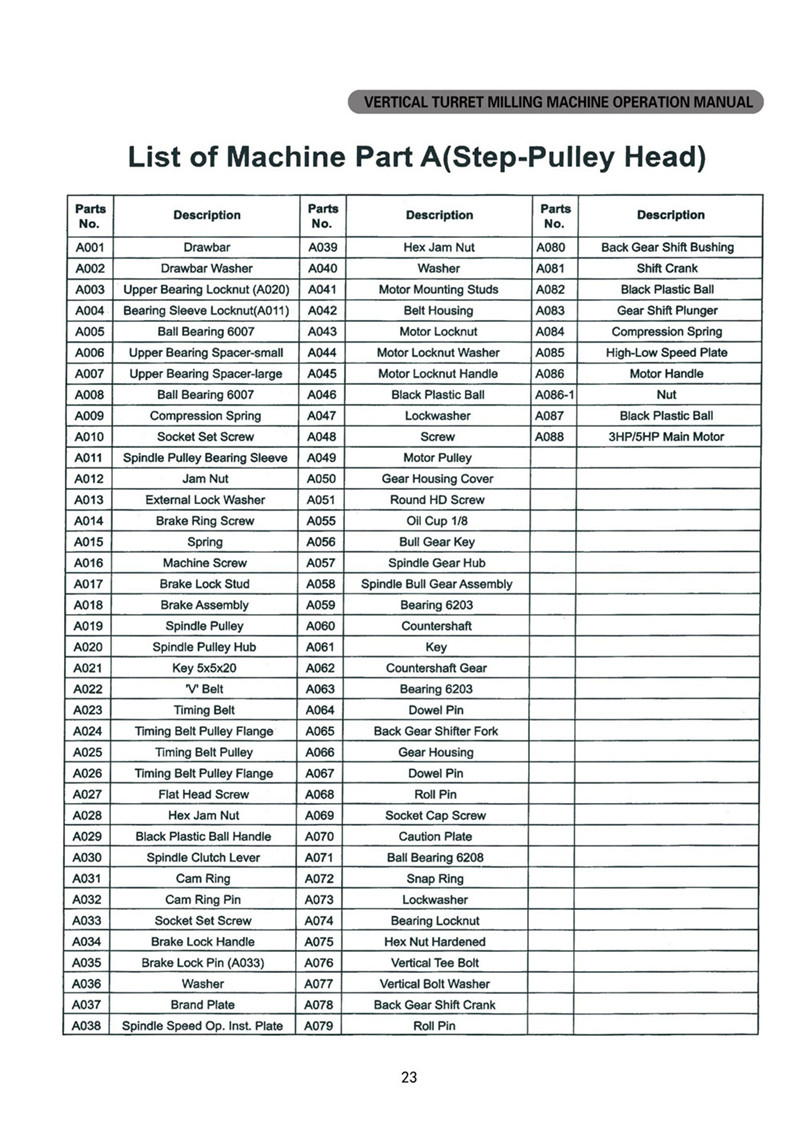

Part 3: Machine Head and Accessories

The machine head is the uppermost part of the vertical turret milling machine and contains the motor spindle , and various accessories. The spindle is the primary cutting tool, and its speed and direction can be controlled to accommodate different machining requirements. Additionally, the machine head can be equipped with various accessories to enhance its functionality, including:

1. Power Feed: A power feed attachment enables automatic movement of the workpiece, reducing the need for manual adjustments and improving efficiency.

2. Digital Readout (DRO): A DRO system provides real-time feedback on the position of the cutting tool, allowing for precise measurements and accurate machining operations.

3. Coolant System: A coolant system helps dissipate heat generated during machining and lubricates the cutting tool, prolonging its lifespan and improving cutting performance.

4. Spindle Speed Control: This accessory allows operators to adjust the speed of the spindle to match the specific requirements of different materials and cutting operations.

Conclusion

Understanding the various components of a turret milling machine and its machine head accessories is essential for maximizing its capabilities and achieving high-quality machining results. By familiarizing oneself with these components, operators can effectively utilize the machine's features and optimize its performance in metalworking and manufacturing applications.

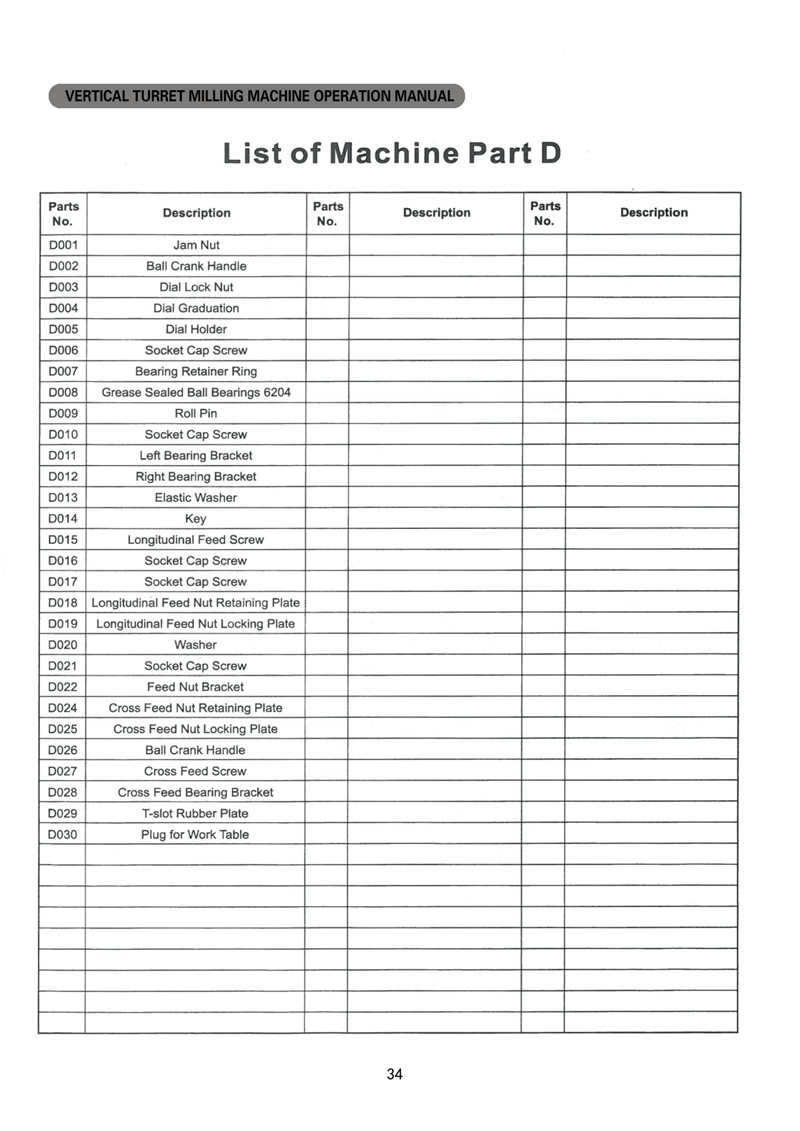

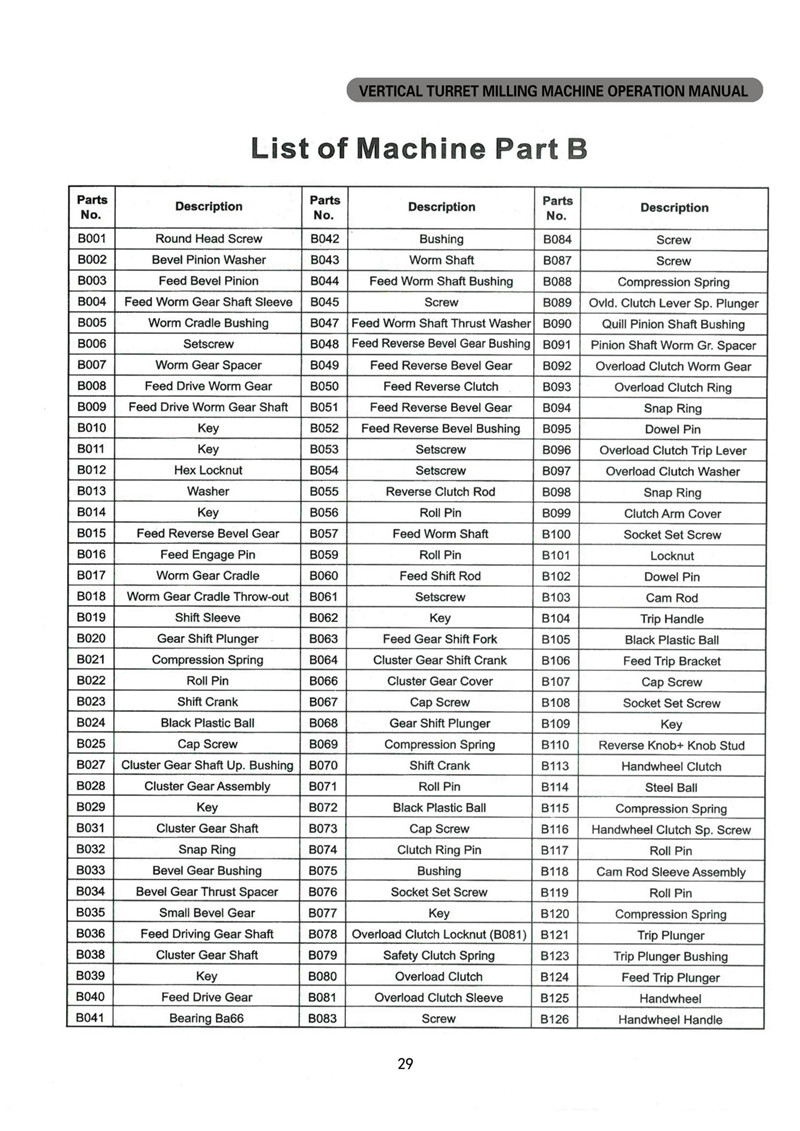

The following are the names and codes of various accessories for turret milling machines. If you need pictures of corresponding accessories, you can contact www.metalcnctools.com or info@metalcnctools.com for getting it anytime.

Post time: Apr-19-2024